|

|  |

|

|

|

Relton Carbide Porcelain Hole Cutter

SAME DAY SHIPPINGFor Installing: Reverse Osmosis Systems, Hot-Water Dispensers, Spa Jets in pre-existing bathtubs

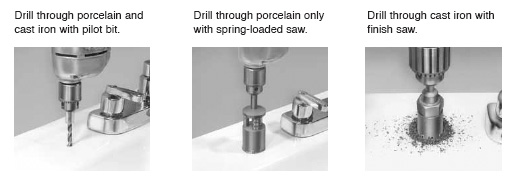

Relton Porcelain Cutter Kits are designed with the Finish Saw 1/8" smaller in diameter than the Porcelain Saw. The Finish Saw diameter is used to determine which kit should be purchased.

Note: Kits are designed for porcelain over cast iron, NOT for solid Porcelain.

Code Name Image Price

Relton Specialty Carbide Hole Saw Catalog (500k pdf)

CARE AND USE OF CARBIDE-TIPPED HOLE SAWS

Relton Carbide-Tipped hole saws are available for use in a wide range of materials, including: metal, wood, plastics, masonry, ceramics, marble and fiberglass. Be sure you have the correct Relton hole saw for your application. Please see page 4 for spring ejector instructions. Relton hole saws can be easily resharpened. The high-quality carbide inserts are replaceable, allowing for complete rebuilding of the saw. Contact the Missouri Precision Tool 1-866-94 TOOLS for more information on the resharpening or rebuilding of your hole saw.

Relton Carbide-Tipped hole saws will provide the lowest cost per hole when the following use and care instructions are observed:

1.) Insert the hole saw shank into the chuck of the power tool properly. If the shank is inserted off center, or the chuck is not tight, vibration may damage the hole saw.

2.) Tighten the shank firmly to the hole-saw head. Allowing the shank to be loose in the head will cause excessive vibration that may damage the cutting teeth and the material being cut.

3.) Hold the hole saw and drive unit as steadily as possible. Use a drill press or drilling fixture when possible. Allowing the drive unit or the hole saw to wobble will create undue stress and may cause the cutting teeth to strip out or the saw head to break.

4.) The saw should be held at a 90° angle to the surface of the material being cut. Sawing on an angle that is not 90 ° to the surface may cause the cutting teeth of the hole saw to contact the material unevenly, thus breaking the saw. There are some types of saws that do allow for an "interrupted cut.'

5.) A recommended RPM table is supplied with these use-and-care instructions. Operate the hole saw near the speed listed in the table. Running the saw faster than the recommended RPM may cause the saw to wear unnecessarily.

6.) Apply adequate pressure on the saw while cutting. Allowing the cutter points to contact the work without applying adequate pressure may cause the cutter points to dull earlier than normal.

7.) Always wear safety glasses and keep fingers and hands away from the saw while it's in operation. Don't wear loose clothing near an operating hole saw.

8.) Cutting fluids, such as Relton Rapid Tap®, Hard-Metal Cutting Fluid, and A-9®, Aluminum Cutting Fluid, can be used on a Carbide-Tipped hole saw to extend cutter life and maintain a clean, consistent cut in metals. If a lubricant Is to be used, it must be applied prior to the heat build-up that occurs when a saw contacts the workpiece.

9.) Relton hole saws should be used in conformity with the power tool manufacturer's specifications.